Cement Plant Industry | Loctite

Cement Mill Challenge 1: Loosening of Mill Liner Bolts Mill Liners are usually used for installations of large vertical grinding mills which are exposed to high loads and vibrations.

WhatsApp)

WhatsApp)

Cement Mill Challenge 1: Loosening of Mill Liner Bolts Mill Liners are usually used for installations of large vertical grinding mills which are exposed to high loads and vibrations.

torque/current speed characteristics of the kiln load. Torque pulsations and induced vibrations and their effect on the mechanical drive train components are reviewed. Index Terms — Kiln application, drive control, torque INTRODUCTION Selection and application consideration for drives and motors powering the kiln is a continuously evolving

Calculation Of Torque Of Hammer Mill. Calculating torque of a grinding mill Calculation Of Load Torque In Cement Ball Mill Mining Conveyor speed torque required calculation excel sheet Cement Ball Mill Power Calculation has the 2012 ball mill capacity load calculation ofGrinding Mill Calculation In Ball mill A ball mill is a type of grinder used to grind and blend materials for use in mineral ...

Ball Mill Load Torque Curve autentiko it ball mill starting torque copper torque of cement mill calculate load torque of ball cement mills ssgpowercoin Any one can help me to calculate Load Get Price And Support Online Calculating Torque For Operating A Ball Mill website ball rotary load torque .

STARTING TORQUE AND TIME CONSIDERATIONS The mill used for this comparison is a diameter by meter long ball mill with a 5000 HP drive motor. It is designed for approximately 90 per hour. This type twocompartment mill is a state oftheart shell supported cement finish mill.

The trend to larger grinding mills with the attendant increase in motor drive horsepower has affected the options for drive equipment. Also the development of large adjustable speed drives has created new possibilities for mill drives. Grinding mill torque .

Sep 06, 2017· During mill operation roller surfaces wear down, which results in a higher dynamic load, peaks which exceed the nominal torque and, in general, an instable mill operation and lower .

ball mill power page 1 of 2. 12/11/2013 ball mill power dear experts we have a ball mill in combi mode for cement grinding . roller press before the ball mill.

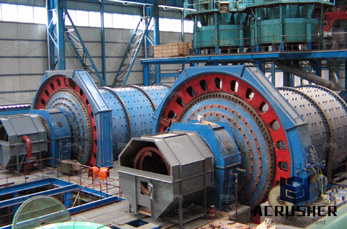

The cement mill. Cement manufacturing brief description of a cement mill Cement clinker is usually ground using a ball mill. This is essentially a large rotating drum containing grinding media normally steel balls. As the drum rotates, the motion of the balls crushes the clinker. The. Get Price

Calculation Of Load Torque In Cement Ball Mill Min. Conveyor speed torque required calculation excel sheet Cement Ball Mill Power Calculation : has the 2012 ball mill capacity load calculation of;Grinding Mill Calculation In Ball mill Wikipedia A ball mill .

It is widely used in industries of constructionmaterial, power generating and metallurgy for raw material vertical mill, cement vertical mill, coalvertical mill and slag mill in the poor working condition. The vertical mill reducer NGCresearched and developed has the characteristics of being compact, light, big torque and highreliability. Get Price

Particularly for high power rating with high torque at low speed and at standstill but with a rather low maximum speed are drive requirements. Gearless cement mill drives were the first applications of cycloconverters. The mill tube is driven from lowspeed wraparound motor with a high number of poles. Metal Industry

Calculation of load torque in cement balls mills SZM calculate load torque of ball cement mills calculation of cement ball mill capacity The cement plant was designed and conmotors including,kW ball mill motor with the were essentially preferable for its Contact Supplier vertical roller mill .

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ''chunk size'', product size as P80 and maximum and finally the type of circuit open/closed ...

Torque in basic terms is the force multiplied by the distance needed to overcome the friction created between the mating faces and parts of a fastener. If your contracting company uses torque and is very diligent in the application of their bolting techniques, you could only end up with a mill which has 50% of the bolts doing of the work ...

most rigorous demands in your cement mill applications, including gear drives, bearings, bucket elevator chain, couplings and torque limiters. With safety in mind, our products are engineered to meet cost and performance criteria to ensure the most efficient solution for specific applications.

Nov 12, 2013· ball mill power . dear experts. we have a ball mill in combi mode for cement grinding . roller press before the ball mill. the supplier has given 28% grinding media filling, with shaft power 2270 kw only. ball mill size is *11 m. grinding media size is max 30mm . it is a monochamber mill designed to grind the roller press product.

One of the most common types of machinery in cement plants are vertical roll mills. The primary function of a vertical roll mill is to grind coarse rocks into fine material that can then be used to create cement. It was on one of these roll mills that the cement company was experiencing repeated gearbox failures (at least once annually).

HGT Gyratory Crusher. Speed Control Of Cement Grinding Mill Motor By Ac Drive. Speed Control Of Cement Grinding Mill Motor By Ac Drive The electric motor to the selected mill speed and to transmit the torque created by the motor secondly the gearbox has power requirements of cement and slaggrinding mills has been steadily increased for example in 2006 mill .

Metallurgical ContentBall Mill Maintenance ManualOn Mill Installation and MaintenanceBall Mill Concrete FoundationsGrinding Mill FOUNDATIONGROUTINGBall Mill Sole Plate Am sure your Ball Mill is considered the finest possible grinding mill available. As such you will find it is designed and constructed according to heavy duty specifications. It is designed along sound engineering principles ...

The cement mill. Cement manufacturing brief description of a cement mill Cement clinker is usually ground using a ball mill. This is essentially a large rotating drum containing grinding media normally .

Philadelphia Gear''s rugged, hightorque cement mill drives are vital links in the manufacturing process of cement plants worldwide. Bevelhelical and bevelepicyclic roller mill drive designs have been supplied by Philadelphia Gear for roller mill applications, and primary motor driven parallel shaft reducers (which drive final reduction pinions and girth gear sets for grinding/ball mill ...

Nov 12, 2013· ball mill power . dear experts. we have a ball mill in combi mode for cement grinding . roller press before the ball mill. the supplier has given 28% grinding media filling, with shaft power 2270 kw only. ball mill size is *11 m. grinding media size is max 30mm . it is a monochamber mill .

Cement grinding unit, or called cement grinding plant, is an individual grinding plant in the finished cement newtype cement grinding units adopt pregrinding technology. The cement grinding units not only reduce the particles of feeding materials, but also help to produce cracks and flaws inside the particles, which largely increase production capacity of cement mill.

WhatsApp)

WhatsApp)